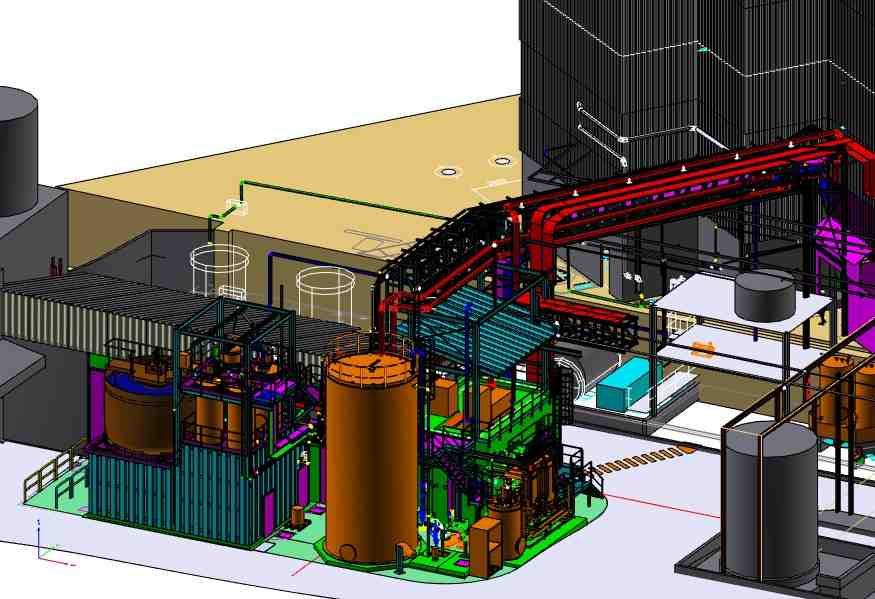

Installation of a station for the recovery of precious metals contained in liquid effluents from catalyst production workshops

Location: Salindres (30)

Project phase: Study, implementation and start-up

Project duration: 18 months

Studies :

- Definition and validation of the treatment process with laboratory tests (physico-chemical treatment completed by an ozonation stage)

- Carrying out material and thermal balances, PID (piping instrument diagram)

- Participation in HAZOP (Hazard and Operability analysis)

- Sizing of all equipment and drafting and follow-up of consultation files up to the selection of the supplier

- Identification of effluent collection points in the various workshops

- Installation of the station in the existing one with installation of an extension

- Drafting of work specifications (civil engineering, structure and framework, piping)

- CAPEX and implementation planning

Realization and start-up :

- Execution studies and follow-up of suppliers during the studies

- Writing of the functional analysis and all documentation for the start-up and operation of the station

- Assistance in starting up and adjusting the installation

Total amount of the project :

Range A < 10 M€

Range B : between 10 and 20 M€

Range C : between 20 and 50 M€

Range D > 50 M€

Note: installation of a complete ozonation system using compressed air

You can find our different realizations on industrial effluents as well as on chemistry and innovative materials by clicking on the links.